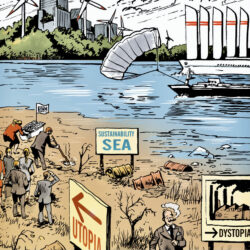

The Statement: Circular supply chains will be hampered by a lack of visibility

Digitalization, globalization, sustainability and the current pandemic are all forcing companies to strategically reassess their business priorities. Supply Chain Media has asked a number of supply chain directors and high potentials for their reactions to various statements, and they are being published in this online series. This week, the statement relates to sustainability and end-to-end supply chain visibility.

The Statement: It will actually be impossible to create circular supply chains over the coming years, because true end-to-end visibility is not taking off, recycled materials are not plannable and (new) raw materials are becoming increasingly scarce.

Theo Wienholts, Chief Operating Officer at Rouveen Kaasspecialiteiten:

“I think this is all true. The growing scarcity of raw materials in particular will really become a challenge. Many new techniques, such as smart contracts, AI and blockchain technologies, are primarily being deployed by either large companies (multinationals) or small ones (start-ups). The great majority of the companies in between are not doing anything in this respect.”

Roland van Bussel, Chief Operating Officer at Moonen Packaging:

“I disagree. Circularity and the use of renewable raw materials is essential in order to meet the growing demand. There are already plenty of opportunities and the pace of development is fast. The challenge lies in whether different organizations have the confidence to really work together on circular solutions and to ensure that they create win-win situations.”

Joost Bous, Supply Chain Director at Action:

“End-to-end visibility is indeed important for proven circularity. However, it’s still possible to take significant steps towards greater sustainability within the existing constraints, such as by using alternative materials, sustainable packaging, electrification, etc. By reducing packaging materials, for example, we have reduced the amount of space needed during transport for a large number of our products. But we’re also looking at recycled materials and the life span of products, and we’re changing designs to improve these aspects. It will continue to be important to work together with suppliers to find smart solutions. In addition, the scarcity of raw materials can actually encourage more cost-effective use of recycled materials.”

“End-to-end visibility is indeed important for proven circularity. However, it’s still possible to take significant steps towards greater sustainability within the existing constraints, such as by using alternative materials, sustainable packaging, electrification, etc. By reducing packaging materials, for example, we have reduced the amount of space needed during transport for a large number of our products. But we’re also looking at recycled materials and the life span of products, and we’re changing designs to improve these aspects. It will continue to be important to work together with suppliers to find smart solutions. In addition, the scarcity of raw materials can actually encourage more cost-effective use of recycled materials.”

Marc van Abeelen, Director Finance at Ricoh Europe SCM:

“The growing scarcity of raw materials means that it’s even more important to further expand the circular supply chain. This can – and will have to – be done in phases… from limited refurbishments in order to directly reuse products that are returned by customers in the local market, up to a global supply chain in which materials are ultimately reused in the manufacture of new products. The first steps provide visibility into the residual value of products and help to predict supply, so that follow-up steps can be taken. To achieve truly effective supply chains, it will also be necessary to make the circular supply chain part of the product design principles and to foster collaboration between different parties/manufacturers. In my opinion, scarcity and the need for organizations to reduce their environmental impact will further accelerate the future development of circular supply chains.”

Willemijn Potjer, Supply Chain Director at Schoeller Allibert:

“Unfortunately, this does seem to be the case. End-to-end visibility sounds like music to our ears, but people seem to be afraid to share data – they are scared of giving away their ‘trade secrets’. Having said that, I want to stay optimistic. The scarcity of raw materials will force us to find ‘healthy’ alternatives, and recycled products are one such alternative. Demand is rising and driving the need for plannability, so this will have to be optimized. Creativity, innovation and the courage to turn ideas into action – exciting times lie ahead for supply chain!”

Mark van de Greijn, Head of Supply Chain & Order Fulfilment at VodafoneZiggo:

“I disagree with this statement. In my opinion, the growing scarcity of (new) raw materials will actually accelerate the creation of supply chain circularity. And recycled materials are plannable, it’s just that the supply (which has to come from returns, etc.) is less predictable so companies have to work with a bigger margin of uncertainty. However, since the recycled products usually have a lower value than new materials, this extra margin will in most cases have only a limited financial impact.”

Michiel van Veen, Director Supply Chain and Business Innovation at Royal Lemkes:

“Through measures like stricter regulations for single-use plastics, governments in various countries are continuously increasing the pressure to improve supply chain sustainability. This will initially lead to small-scale breakthroughs in the area of multi-use packaging, for instance, such as sustainable trays in the European floriculture sector.”

“Through measures like stricter regulations for single-use plastics, governments in various countries are continuously increasing the pressure to improve supply chain sustainability. This will initially lead to small-scale breakthroughs in the area of multi-use packaging, for instance, such as sustainable trays in the European floriculture sector.”

Raymond van der Putten, Supply Chain Director at Zuiver:

“I agree. Suppliers in Asia, for instance, are already finding it difficult to prove the origin of timber (EUTR), let alone of recycled materials. That will take a few more years. Perhaps the scarcity of raw materials will accelerate this process.”

Pieter-Jelle van Dijk, Director of Operations at Ricoh Europe SCM:

“In view of the rising number of ‘as-a-service’ models, companies need to take more responsibility for the assets they use and ensure that they are redeployed economically. I also expect that products will be used for longer in the future because they will be increasingly repaired. Last but not least, higher raw material prices will make the reuse of raw materials more attractive.”

Arthur van Och, Supply Chain Director at ForFarmers:

“There is no one-size-fits-all solution for a circular supply chain. In our sector, however, there is already much more circularity than many people realize. Around 25% of our volume comes from the sale of dry moist liquid (DML) products, which include residual flows from the food industry – such as whey from cheese producers, chocolate flakes, potato peel, barley that is not suitable for use in brewing, etc. These products are used as ingredients in compound feed, but are also sold separately. These residual flows and by-products are converted into high-quality foodstuffs (milk, meat and eggs) for human consumption. Meanwhile, the manure produced by the livestock is in turn in crop production. So there is definitely a nutrient cycle.”

Ardjan van der Blonk, Supply Chain Director at Alliance Automotive Benelux:

“I disagree, because I expect the scarcity of raw materials to actually stimulate the use of recycled products. End-to-end visibility will require investments, but more money will be made available – and sooner – because the need will be crystal clear.”

Peter Wijnen, Director of Operations at IFF International Flavors & Fragrances:

“The hallmark of a circular supply chain is identifying and assigning value to a waste flow or by-product. Once the value of the waste flow has been established, a new, technical nutrient is born that further serves as a raw material for another product, often in a different industrial sector. This approach has already been applied in various industries on both a large and a small scale. There are small-scale examples of circular supply chains for technical materials that pursue zero waste of materials from the ecosphere, such as the reuse of cooking oils and fats in the production of biodiesel and other fuels. On a larger scale, PET bottles are reused in the textile industry. Circular supply chains are not limited to technical materials; it is also becoming increasingly common to identify value in waste flows or residual flows of biological materials and pursue zero waste. Recognizing the value of residual flows requires different industrial sectors to work together. Cross-sector supply chain management must therefore be promoted and find its way into boardrooms. Rather than looking to supply chain technology to create circular supply chains, it is about recognizing the value of waste flows – in combination with fostering consumer awareness, which should create the pull effect in the supply chain.”

“The hallmark of a circular supply chain is identifying and assigning value to a waste flow or by-product. Once the value of the waste flow has been established, a new, technical nutrient is born that further serves as a raw material for another product, often in a different industrial sector. This approach has already been applied in various industries on both a large and a small scale. There are small-scale examples of circular supply chains for technical materials that pursue zero waste of materials from the ecosphere, such as the reuse of cooking oils and fats in the production of biodiesel and other fuels. On a larger scale, PET bottles are reused in the textile industry. Circular supply chains are not limited to technical materials; it is also becoming increasingly common to identify value in waste flows or residual flows of biological materials and pursue zero waste. Recognizing the value of residual flows requires different industrial sectors to work together. Cross-sector supply chain management must therefore be promoted and find its way into boardrooms. Rather than looking to supply chain technology to create circular supply chains, it is about recognizing the value of waste flows – in combination with fostering consumer awareness, which should create the pull effect in the supply chain.”

Edgar Beers, Director BU Sourcing & Supply Chain at Sitech:

“I would say it’s the precisely other way round: the growing scarcity of (new) raw materials is driving the reuse of existing ones. Recycling is not the answer – upcycling is. It will soon be effective and valuable to own raw materials and make them available. End-to-end visibility is not that difficult, as long as you work in a closed loop. That’s precisely the breakthrough that is needed now: the step from a global supply network to closed loops with defined interfaces with other loops.”

Wiggert Deelen, Senior Director Global Supply Chain Transformation at Heineken:

“Visibility is interesting to improve the performance of a supply chain, but it’s not essential. Large stocks are held of a great many raw materials.”