Supply chain trends: look at your innovation drivers

From blockchain to robotic process automation and from 3D printing to machine learning – which trends should you focus on to advance your supply chain? The advice of Martijn Lofvers, Chief Trend Watcher at Supply Chain Media, is to investigate which innovation drivers are relevant to your own supply chain. This message set visitors thinking during his presentation at a recent trade event. “I’m going to critically review our innovation drivers,” said one attendee afterwards.

By Marcel te Lindert

The anticipated economic decline caused by the pandemic actually lasted just six months. Since then, the economy in the Netherlands and elsewhere has been growing again, and most recently by as much as 3% or more. However, this growth is accompanied by sizable bullwhip effects in international supply chains. Costs for companies are rising due to higher transport and energy prices combined with shortages of parts and labour. The rate of inflation is rising too, now that these costs are increasingly being passed on to customers. “And if inflation spirals, we might end up in a recession after all – especially if China decides to attack Taiwan,” said Martijn Lofvers during his presentation on supply chain trends at the ICT & Logistiek trade show in the Dutch city of Utrecht.

Innovation drivers

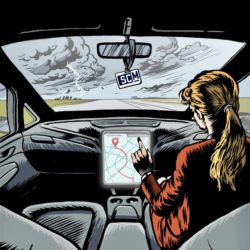

The chief trend watcher likened the current position of companies to a ship in a storm at sea, being battered by one huge wave after another. “Look around you. Which waves are about to hit your company? And which waves are coming behind them? You need to try to steer your ship between them,” said Lofvers, who recommended the trend compass as a useful instrument in this context. “If you do nothing, your ship will simply be tossed around on the waves. So focus on your own ‘North Star’ and use the trend compass to select the right route.”

The trend compass lists megatrends that impact almost every business, such as globalization, digitalization and sustainability. But there are also macrotrends that are more relevant for some companies than others, such as the focus on cost reduction, personalization, convenience or the experience. Lofvers referred to these trends as ‘innovation drivers’. “For companies that are focused on process optimization, the important innovation drivers are low cost and convenience. Take Amazon, for example. Jeff Bezos realized years ago that the only way to beat the competition was to achieve the lowest order-pick cost per SKU. But for companies focused on providing optimum customer service, the key innovation drivers are personalization and the experience.”

The role of the business strategy

Which innovation drivers are important for which company depends on the chosen business strategy. In essence, companies can choose between three strategies: product leadership, operational excellence and customer intimacy. The focus is on the product in the case of product leadership, on the processes in the case of operational excellence and on the service to customers in the case of customer intimacy. Irrespective of which strategy a company chooses, they should align their supply chain strategy with it – but too many businesses are failing to do this, according to Lofvers: “80% of companies have not aligned their supply chain strategy with their corporate strategy. They often don’t even have a supply chain strategy, and therefore no inventory strategy either. These are the companies that are now having issues with delivery reliability.”

In practice, Sales often opts for customer intimacy, Marketing for product leadership and Supply Chain for operational excellence. Lofvers mentioned Philips as an example: “This multinational wanted all three options at once, but that pulls your company in different directions. Choose one strategy and fully commit to it. That strategy dictates which innovation drivers – and therefore which trends and technologies – are interesting for your company,” he stated.

Critical review of innovation drivers

One of the members of the audience was Remco Witteveen, Supply Chain Director of technical wholesaler Isero. The presentation about trends and innovation drivers set him thinking: “I’m going to double-check whether our innovations are generating the right added value for our value proposition. By critically reviewing our innovation drivers, we might be able to get even more out of our current developments.”

This critical view is necessary because Isero pursues a strategy of both customer intimacy and operational excellence. In practice, this means that Isero takes its commitment to customer service quite far. “Customers can indicate their preferences and we do our best to take them into account. But in order to maintain this tailored approach at the front end, we have to keep a close eye on costs at the back end. We’re aware of the risk of pulling the company in two different directions, as Lofvers cautioned. That’s why we constantly ask ourselves where customer intimacy ends and operational excellence begins,” said Witteveen.

He cited the company’s logistics network set-up as an example. From an operational excellence perspective it should ideally be based on a centralized distribution model, since that would be the most cost-efficient solution. “But we’ve opted for a decentralized distribution network comprising a central hub plus a large number of branches that also serve as distribution centres. Those branches enable us to deliver to our customers up to twice a day. Speed is important to us. Most customers receive their orders on the next day or on fixed delivery days, but we also deliver a significant number of our orders on the same day.”

The slides from Lofvers’ presentation at the ICT & Logistiek trade show can be downloaded below.