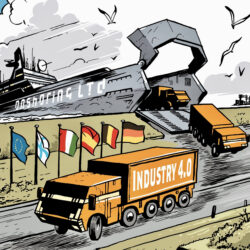

Supply chain network design: from globalization to regionalization

The article delves into the trend of reshoring, where companies are moving their production capacities closer to their primary markets to improve supply chain resilience, reduce lead times, and enhance sustainability. The COVID-19 pandemic highlighted vulnerabilities in global supply chains, prompting companies like Sandvik to re-evaluate their manufacturing strategies. Sandvik, which has significant production in Europe, is expanding with a new factory in Malaysia to better serve its markets in Asia and Australia, aiming to reduce supply chain disruptions and inventory pressures.

Research by BCI Global and Supply Chain Media reveals that almost half of the surveyed companies have shifted production from China to other regions like Southeast Asia, Europe, and North America, driven by the need to shorten supply chains, enhance resilience, and reduce transport costs. Despite this, the majority of these companies have not closed existing factories but have instead added new facilities to meet growth demands and navigate supply chain complexities.

Building a regional supplier ecosystem is a major challenge in reshoring. Companies like Sandvik and others are struggling to find local suppliers with the necessary capacity and capabilities. This issue often forces reliance on suppliers from other regions, which can undermine the benefits of relocating production.

The article also discusses the impact of geopolitical tensions, trade wars, and rising production costs in China, which have accelerated the reshoring trend. Companies are increasingly producing closer to their sales markets, not just to reduce dependence on China, but also to improve agility and reduce risks. The reshoring trend is seen as a strategic shift rather than a temporary response to disruptions.

Furthermore, sustainability is becoming a critical factor in supply chain decisions. The article highlights the role of the Carbon Border Adjustment Mechanism (CBAM), which aims to level the playing field by imposing levies on imports based on their carbon emissions. This measure is expected to influence reshoring decisions significantly, as it makes importing certain goods more expensive, encouraging companies to produce locally.

Lastly, the article touches on the importance of working conditions and compliance with environmental, social, and governance (ESG) goals in shaping production site choices. Companies are increasingly considering sustainability in their decision-making, influenced by regulations like the USA’s Uyghur Human Rights Policy Act and Germany’s Supply Chain Act, which aim to ensure ethical labor practices in supply chains.

Find more whitepapers of Supply Chain Movement here >>