Intersteel invests in data science to achieve better forecasting

Geopolitical, economic and sustainability-related developments are all putting increasing pressure on supply chains. To make supply chains more resilient, you need to innovate – but how? During Supply Chain Media’s fourth SCM Talkshow, Véronique Sonsma provided insight into her approach within Intersteel. Besides working with innovative start-ups, she has also invested in her own development, because “Supply Chain and Data Science don’t always speak the same language”.

By Marcel te Lindert

At Intersteel, a manufacturer of hardware for doors and windows, innovation first and foremost means product innovation. Just last year, the company won the Red Dot Design Award with Shiraat, a slender, extra-long door handle. But innovation also means process innovation, including within Intersteel’s supply chain. Véronique Sonsma personally invested in this by participating in the Lead Business Translator training at the Jheronimus Academy of Data Science (JADS). This intensive course took up a sizable portion of Sonsma’s time for 18 months.

“We’ve all noticed that data science has very stealthily crept into the supply chain, but also that Supply Chain and Data Science don’t always speak the same language,” said Intersteel’s Director of Operations during the SCM Talkshow, which was broadcast from the Media Cows TV studio in the Dutch village of Wehl.

Better forecasting

During the training, Sonsma learnt how to translate a supply chain issue into a data science issue and vice versa. “This is a grey area that not too many people are working on yet, but it’s important to bring the supply chain and data science worlds together. Which questions should a supply chain specialist ask so that a data scientist can come up with effective solutions rather than sub-standard ones? One question is which data to use to train your data science models. If there is a bias in that data, it can really throw you off track.”

Within Intersteel, she uses the knowledge she has learned to improve forecasting. Grouping certain product categories together, or focusing on colours, creates new insights into customer demand trends. “Black door handles have been very popular in recent years. So it’s very tempting to introduce new black models, but these would have a cannibalizing effect on the existing ones. The data science model we’ve now developed gives better insight into the total demand for black door handles. We already had a forecasting system, but it didn’t always tell the whole truth in that respect.”

Working with start-ups

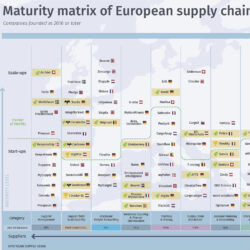

Innovation also means working with start-ups. One of the start-ups chosen by Intersteel is Responsibly, winner of last year’s European Supply Chain Start-up Contest organized by Supply Chain Media. ‘‘We’re not a big company, so we have to be smart,” stated Sonsma. “If you can’t open your own office in Asia and therefore can’t be present every day, it’s quite difficult to build and maintain relationships with suppliers there – and especially to assess them in terms of corporate social responsibility (CSR). The start-up Responsibly helps us monitor our suppliers remotely.”

Intersteel’s other partner is GoodShipping, although it has now outgrown the start-up phase. “We would like to reduce our carbon emissions, and not just by introducing more environmentally friendly packaging. But we can’t do that in every part of the supply chain, such as container transport, so we decided to work with GoodShipping to offset those emissions.”

Listening to pitches

Sonsma first met both GoodShipping and Responsibly during the inNOWvate Supply Chain Event. So what made her decide to work with these two young, innovative companies? “I listened to their pitches and asked myself which problem they could solve for me – and whether I actually had a problem in their area. During Responsibly’s pitch, I heard how I could get more grip on my suppliers’ CSR behaviour. At the same time, I saw opportunities to innovate together. We can feed our challenges into Responsibly, and they can develop new solutions.”

Intersteel definitely intends to keep innovating. Sonsma would like to increase the use of data science to improve forecasting. “Look at what’s happening in the housing market. Many construction projects are currently delayed or on hold, but the Netherlands’ housing shortage will have to be resolved sooner or later. Our revenue is largely dependent on those construction projects. I would like to incorporate more information about housing-market developments into our models, such as data on the number of building permits issued.”

Outside input

Sonsma concluded with some advice for other small and medium-sized enterprises, because – as she said – if you’re not big, you have to be smart. “Above all, look closely at what others are doing. In the past, I worked at larger companies such as Nike and Philips and I certainly gained some insights from them. And stay open to input from outside; seek contact with other supply chain professionals. Keep learning and acquiring new knowledge.”