Increasing risks require new S&OP competences

Many companies started with Sales & Operations Planning in the pre-COVID era. But how can you do S&OP now that uncertainty and unpredictability have increased so dramatically? During a Webinar Wednesday, Involvation explained which five competencies contribute to a strong and resilient supply chain and should be integrated into the S&OP process. “A company that wants to strengthen its resilience will have to change the way it thinks and acts.”

By Marcel te Lindert

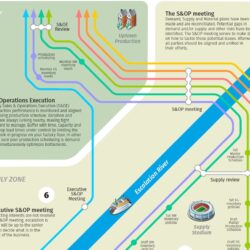

Consultancy firm Involvation has been helping companies implement Sales & Operations Planning for many years. As a result, these companies now have a rolling, consensus-based planning process with a monthly cycle. “That’s a good development,” stated Jeroen Scheepers, partner at Involvation. “But in this traditional form of S&OP, the focus is on normal, day-to-day operations. In today’s disruptive times, we also have to work on issues like risk management and move towards a stronger, more resilient form of S&OP.”

In collaboration with the University of Groningen and Windesheim University of Applied Sciences, Involvation has developed a model for creating a resilient supply chain. This requires five competences, which companies should integrate into their S&OP process: redundancy, collaboration, flexibility, transparency and agility. “A resilient supply chain requires the right mindset,” said Alfons Willemsen, also a partner at Involvation. “If you have had a heart attack, it is time to change your lifestyle. That speeds up your recovery and reduces the chances of it recurring. A company that wants to strengthen its resilience will likewise have to change its way of thinking and acting.”

Redundancy

Redundancy is about creating buffers. Willemsen referred to the start of the pandemic in 2020, when car manufacturers in particular struggled with disruptions in their supply chains. “We built a model that allowed us to predict the bullwhip effect in this sector. If you see that coming, you can take it into account in your S&OP process. Then you can use your buffer stocks to balance supply and demand and cushion the bullwhip effect.”

Buffers exist not only in the form of stocks, but also in the form of capacity, time and money. Scheepers cited the example of a food manufacturer that uses capacity as a buffer. “If the capacity utilization of a production line exceeds 80%, the planners see an orange flag. Above 85%, they see a red flag. Why? Because a high utilization rate has an impact on the ability to respond to fluctuations in demand,” explained Scheepers. “This is the perfect example of a decision for the S&OP process. If you decide to use extra capacity, you have to accept that flexibility decreases.”

Collaboration

By collaboration, Involvation means joint decision-making with internal and external partners. This involves S&OP, but also cooperation on risk management. One form of this is Vendor Managed Inventory (VMI). Scheepers mentioned the example of a fertilizer supplier with insight into the stock levels of 1,500 fertilizer silos at agricultural and horticultural companies. “That gives the supplier many more options in replenishing those silos.”

Willemsen knows of chemical companies that maintain VMI relationships with large customers. “They use these VMI stocks in their S&OP process as a kind of future stock point. That allows them to decide every month whether they need to replenish those stock points or can afford to drop stock levels some more. That is a big help in better balancing supply and demand.”

Flexibility

Flexibility is about having multiple options to deal with volatility and uncertainty. Think about extra options in the transport network in case a disruption arises such as the current one in the Red Sea. Or think of contractual agreements with suppliers that allow room to adjust volumes. “But also think about flexibility in product design. In the automotive industry, we see several examples of modular design, where different brands use the same platform,” said Scheepers. He stressed that any S&OP process should start with discussing the product portfolio. “That is the time to start the conversation about modular design and reducing complexity.”

Flexibility is also about scenario planning, Willemsen explained: “When you think in terms of options, you think in scenarios. That is perhaps the most important point in strengthening resilience: continuously discussing the assumptions underlying those scenarios. Tools for scenario planning can support you in this, but don’t wait for them.”

Transparency

Increasing transparency starts with supply chain analysis. Who are your suppliers and customers? “If you know what their bottlenecks and challenges are, you can include them in the S&OP process,” stated Scheepers. “Many tools focus on disruptions in the supply chain, such as a port strike. How should you respond to that? But it is also important to know who are the suppliers of your suppliers, and the customers of your customers.”

Willemsen elaborated on early warning systems for disruptions. “Sometimes you can see those disruptions coming well in advance. Last year, salary negotiations took place at ports on the west coast of the United States, resulting in strikes. Later this year, salary negotiations are taking place at east coast ports. That could be a very early warning. Include that in your S&OP discussions.”

Agility

The last competence concerns agility: the speed with which companies can respond to disruptions. This requires short lead times, but also fast decision-making processes. “We can use artificial intelligence to speed up planning processes and make better decisions,” said Scheepers. “We have a customer that uses artificial intelligence to scan the internet for competitors’ promotional campaigns. The company uses that information in its own planning.”

Willemsen emphasized that the monthly cycle in S&OP should not become a dogma, however. “I worked for a chemical company that was struggling with shortages and had only a few days’ worth of stock left instead of three weeks’ worth. So we went through the S&OP cycle twice a week rather than once a month. As a result, we were able to increase our market share significantly,” the consultant recalled. “If you have a well-running S&OP process, it should be no problem to speed up the decision-making process in emergencies.”