Joost Bous: ‘‘Accept the increase in disruptions and their impact’’

Cost-cutting is once again the number-one topic in boardrooms right now. Due to the steep rise in inflation, companies are having to pull out all the stops to maintain profitability. During the first online meeting of the SCM Directors Club, Joost Bous, former supply chain director of retailer Action, encouraged attendees to think about the medium term and long term as well as the short term. That is the only way to make supply chains more resilient, he said.

By Marcel te Lindert

Nearly 50 Dutch supply chain executives were asked which two megatrends will most affect their business in the long term. Sustainability and the scarcity of raw materials and components topped the list of replies, followed at some distance by digitalization (49%). Joost Bous expressed his surprise, not at the high score of sustainability and shortages, but at the low scores of geopolitical developments (29%), globalization (14%) and pandemics (10%). “I had expected these trends to be much more top of mind, especially after what we’ve been through in the past few years.”

It is precisely these trends that call for a different perspective on supply chains, Bous argued. “Over the past 20 years, we have optimized our supply chains in terms of quality, costs and inventory levels. Traditionally, these are the three KPIs for supply chains. But we’re now seeing that our supply chains have become very susceptible to disruptions. To improve the resilience, we need a different set-up. This means that in addition to quality, costs and inventory levels, we’ve got two new KPIs: agility and resilience.”

Back to the drawing board

Last year, in conjunction with McKinsey, Bous gave a presentation on supply chain resilience. It included a list of nine disruptions that have impacted virtually every business in recent years, from the coronavirus pandemic to the war in Ukraine and from the microchip shortage to inflation. “We could easily add another nine disruptions to that,” Bous said. “The number of disruptions is increasing and their impact is growing – that’s a fact. Today’s complex supply chains extend all around the world, and all the interdependencies make them extremely vulnerable.”

Joost Bous experienced this first-hand during his time at Action. “We had just completed a transformation, including supply chain redesign. Everything was in place and the results were fine, until the pandemic broke out in early 2020. So we had to go back to the drawing board. How can we source from other types of suppliers? Which stock levels should we maintain? How can we handle peaks in demand? The pandemic taught us to look at the supply chain in a different way and to plan for scenarios. We learned a different approach to decision-making.”

Primarily a short-term focus

In Supply Chain Media’s survey of nearly 50 supply chain executives, they were also asked which two topics currently receive the most attention at board level. Operational excellence and cost savings scored highest (49%), closely followed by customer excellence and portfolio optimization (47%). Risk management and resilience (35%) and sustainability (31%) were lower down on the agenda. “I expected the latter two topics to score more highly, especially given the experiences of the past two years,” commented Bous.

The high scores for operational excellence and cost savings are undoubtedly due to the current high level of inflation. Bous admitted that he sees companies struggling to maintain profitability, but said this suggests that many companies are primarily focused on the short term. “Successful companies with resilient supply chains plan at three levels: operational, tactical and strategic. At the operational level, it’s important to have a department that is good at firefighting. But it’s also important to make a start on scenario planning. Think about which scenarios could occur, and how to prepare for them tactically.”

Less firefighting

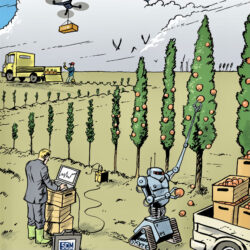

At the strategic level, it is about supply chain design. Where is the best place to source? Which are the critical parts of the supply chain that need to be duplicated? And how can modern digital technologies such as artificial intelligence and the Internet of Things be leveraged to create a multi-directional flow of supply chain information? “At Action, we initially spent most of our time on firefighting. But the better you can plan and organize things in the medium and long term, the fewer fires you have to tackle.”

McKinsey has defined seven building blocks for a resilient supply chain. “The most important thing is to realize that the world has changed: that all kinds of disruptions can occur, and that we need to think about how to protect ourselves against them. Once that realization is there, the rest is a logical extension of it. You understand that it’s key to increase transparency so that you know where the biggest bottlenecks are. You ensure that you receive early-warning signals when something is wrong. And you alter your supply chain design and set to work on topics such as demand shaping,” Joost Bous explained. “Shit happens, whether we like it or not. That realization has to sink in at board level as well.”